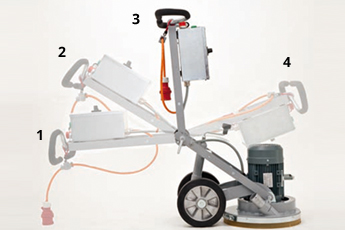

FloorFex EFS 280 LIGHT

fast, efficient grinding, abrading and rasping with diamond tools

High speed single disc machine in 2 versions: LIGHT and HEAVY

- New dust extraction technology

- Guide handle infinitely variable

The EFS 280 FloorFex is an innovative, robust, high speed single disc machine with 6 tool fixtures for diamond grinding, abrading and rasping tools. 2 models are available.

Areas of application

1. Diamond grinding of screed, concrete, coatings, filler, thin layers of paint, etc.

2. Diamond abrading of bitumen adhesive and felt paper, filler and various other adhesives - PU, synthetic resin and tile adhesives, etc.

3. Diamond rasping: removes thin layers of adhesive or thick layers of paint on screed or filler. Also for keying and roughening coatings etc.

Model 230 V LIGHT

This somewhat lighter model is suitable for use in residential construction and on smaller projects. It is powered with 230 V (time-lag fuse 13 A). This model has a soft start and achieves a speed of 1420 rpm.

Model 400 V HEAVY

This high power three phase current version has the following special features: Thanks to a motor with two windings, 2 speeds are possible.

- 2850 rpm at 3.2 kW is used for work on hard sub-flooring such as concrete, coatings or on hard screed, or for the removal of adhesive on filler.

- 1420 rpm at 2.6 kW is used for work on less durable sub-flooring. The tools are less aggressive so that the surface is not treated too harshly.

| Technical Data LIGHT |

| Voltage |

230 V |

| Power |

2.2 kW |

| Speed |

1420 rpm |

| Ø tool |

280 mm |

| Weight |

61 kg |

| Grinding pressure |

32 kg |

Integrated ampere meter

| Technical Data HEAVY |

| Voltage |

400 V |

| Motor can be set to two speeds: |

| 2 Speeds |

Power |

| 1420 rpm |

2.6 kW |

| 2850 rpm |

3.2 kW |

| Ø tool |

280 mm |

| Weight |

78 kg |

| Grinding pressure |

33 kg |

Tools and accessories EFS 280

Thanks to the large wheels the machine moves easily across surfaces. The tools are buffered and fitted with a quick-change system.

The dust hood has been completely redesigned. It is no longer fixed rigidly and is fitted with a double, flexible sealing ring guaranteeing dust protection.

The suction nozzles are wearing parts. Their position can be adjusted to achieve the most efficient dust extraction.

Tool segments are changed fast.

Dust hood

Sucction nozzles

The guide handle is jointed and the height is infinitely adjustable to the required hight thanks to a spindle. It can be locked in four different positions.

Position 1: The handle can be tipped back into a horizontal position, level with the motor for work under built-in fixtures.

Spindle / The fold-away guide handle saves space during transportation.

Position 2: The handle forms one straight line – the optimum working position.

Position 3: To move the machine across a floor when it is not in operation, simply lock the handle in an upright position and tip the machine back onto its wheels.

Position 4: During transportation the handle can be folded forwards to reduce its pack size.

The guide handle can be locked in four different positions.

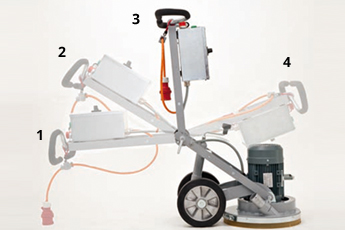

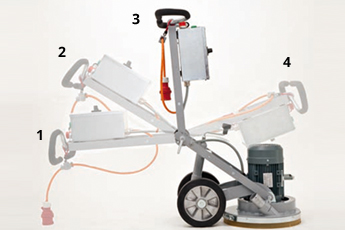

FloorFex EFS 280 LIGHT

fast, efficient grinding, abrading and rasping with diamond tools

High speed single disc machine in 2 versions: LIGHT and HEAVY

- New dust extraction technology

- Guide handle infinitely variable

The EFS 280 FloorFex is an innovative, robust, high speed single disc machine with 6 tool fixtures for diamond grinding, abrading and rasping tools. 2 models are available.

Areas of application

1. Diamond grinding of screed, concrete, coatings, filler, thin layers of paint, etc.

2. Diamond abrading of bitumen adhesive and felt paper, filler and various other adhesives - PU, synthetic resin and tile adhesives, etc.

3. Diamond rasping: removes thin layers of adhesive or thick layers of paint on screed or filler. Also for keying and roughening coatings etc.

Model 230 V LIGHT

This somewhat lighter model is suitable for use in residential construction and on smaller projects. It is powered with 230 V (time-lag fuse 13 A). This model has a soft start and achieves a speed of 1420 rpm.

Model 400 V HEAVY

This high power three phase current version has the following special features: Thanks to a motor with two windings, 2 speeds are possible.

- 2850 rpm at 3.2 kW is used for work on hard sub-flooring such as concrete, coatings or on hard screed, or for the removal of adhesive on filler.

- 1420 rpm at 2.6 kW is used for work on less durable sub-flooring. The tools are less aggressive so that the surface is not treated too harshly.

| Technical Data LIGHT |

| Voltage |

230 V |

| Power |

2.2 kW |

| Speed |

1420 rpm |

| Ø tool |

280 mm |

| Weight |

61 kg |

| Grinding pressure |

32 kg |

Integrated ampere meter

| Technical Data HEAVY |

| Voltage |

400 V |

| Motor can be set to two speeds: |

| 2 Speeds |

Power |

| 1420 rpm |

2.6 kW |

| 2850 rpm |

3.2 kW |

| Ø tool |

280 mm |

| Weight |

78 kg |

| Grinding pressure |

33 kg |

Tools and accessories EFS 280

Thanks to the large wheels the machine moves easily across surfaces. The tools are buffered and fitted with a quick-change system.

The dust hood has been completely redesigned. It is no longer fixed rigidly and is fitted with a double, flexible sealing ring guaranteeing dust protection.

The suction nozzles are wearing parts. Their position can be adjusted to achieve the most efficient dust extraction.

Tool segments are changed fast.

Dust hood

Sucction nozzles

The guide handle is jointed and the height is infinitely adjustable to the required hight thanks to a spindle. It can be locked in four different positions.

Position 1: The handle can be tipped back into a horizontal position, level with the motor for work under built-in fixtures.

Spindle / The fold-away guide handle saves space during transportation.

Position 2: The handle forms one straight line – the optimum working position.

Position 3: To move the machine across a floor when it is not in operation, simply lock the handle in an upright position and tip the machine back onto its wheels.

Position 4: During transportation the handle can be folded forwards to reduce its pack size.

The guide handle can be locked in four different positions.