EFS 700 vario: one machine for every job!

- Grinding: diamond, paper, sanding screens

- Polishing

- Oiling, waxing

- Milling (PCD, WCT)

- Removing residual adhesive

- Grinding Terrazzo (wet/dry)

| Technical Data |

| Motor |

Asynchronous motor |

| Voltage |

230 V / 50 Hz |

| Power |

2.2 kW |

| Speed |

100 - 700 rpm |

| Weight |

58 kg without weights/plate |

| Protection |

Class I insulation |

| Dimensions: |

|

| Machine |

Ø 440 mm |

| Tool |

Ø 400 - 430 mm |

| Guide handle |

Length 110 cm,

width 45 cm |

Thanks to state-of-the-art frequency converter technology, the EFS 700 vario functions flexibly in a speed range of between 100 – 700 rpm.

As a result you only need to have one machine on site: for sub-flooring preparation, grinding, milling and finishing.

As the machine can be disassembled simply and quickly; only one person is required to carry it up steps to higher floors.

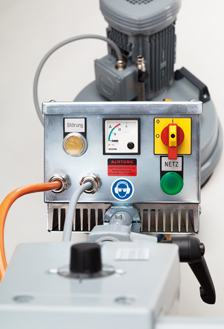

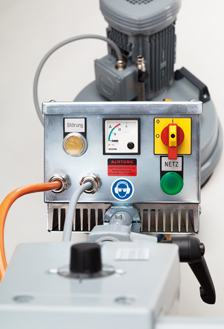

Clearly arranged control panel

State-of-the-art frequency converter technology

The EFS 700 vario is supplied with two additional weights, assembly tools, and a dust protection ring for direct dust extraction. The use of a suitable dust extractor, such as the RONDA 200, is absolutely necessary in order that the considerable volume of dust is extracted as it is generated. This is important in order to guarantee the smooth-running of the machine. Furthermore it also protects the environment.

The motor's electronic control unit monitors all values such as current, voltage, temperature and torque, thus protecting the motor from overloading.

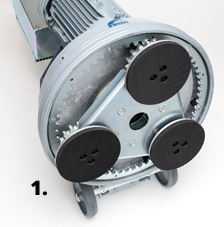

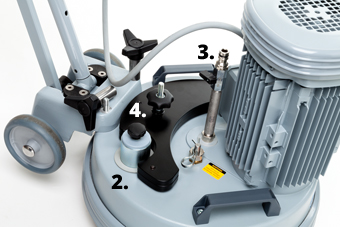

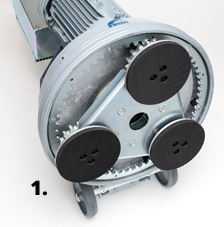

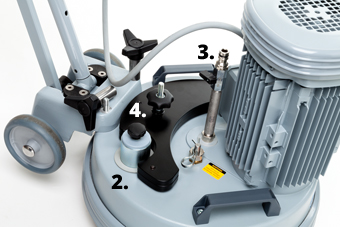

1. Planetary gearing for using driven tools; thus converting a single-disc machine into a contra-rotating three-disc machine

2. Additional dust extraction outlet for grinding with sanding screens

3. Centrally located water supply for wet work

4. Further additional weights for milling work

Tools and accessories EFS 700 vario

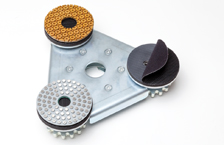

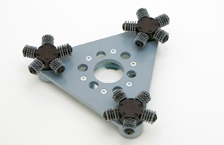

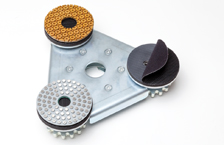

Base plate for grinding with driven tool fixture for contra-rotating application. Hook-loop fastener on the base plate is protected by using an additional exchangeable hook-loop adapter.

3 flexible diamond grinding discs

(resin or metal bonded) Ø 125 mm

Base plate for grinding with driven tool fixture for contra-rotating application. Hook-loop fastener on the base plate is protected by using an additional exchangeable hook-loop adapter.

3 grinding discs, paper Ø 150 mm

Pad base plate, with hook-loop fastener and sponge rubber, Ø 400 mm, for the use of pads (Ø 410 mm) for cleaning and polishing, for applying wax and oil and for grinding with sanding screens.

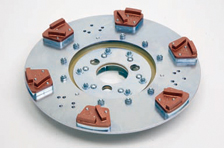

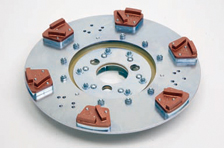

Diamond base plate, buffered, Ø 400 mm, for various tools; e.g. 6 diamond trapezoidal tools for large-surface coarse sanding of screed, concrete, etc.

PCD base plate, buffered, Ø 400 mm, with various tools; e.g. with 6 PCD DFS-1 S segments and depth control when milling. For the removal of any kind of stubborn adhesive (PU, bitumen, synthetic resin, etc.) and filler or for milling screed or tile adhesive. Extremely efficient with a long service life.

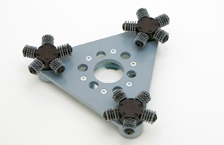

WCT base plate, buffered, Ø 425 mm, with 3 rotating WCT cutting heads, 2.5 mm, pointed, for thin adhesives and paint – even on wooden floors. Or WCT, 4 mm for adhesives or filler on very soft screeds.